Dongguan City Jiexin Electromechanical Equipment CO., LTD.

15+yrs Professional High-speed connectors & Fakra Cable assemblies automated assembly line & solutions

15+yrs Professional High-speed connectors & Fakra Cable assemblies automated assembly line & solutions

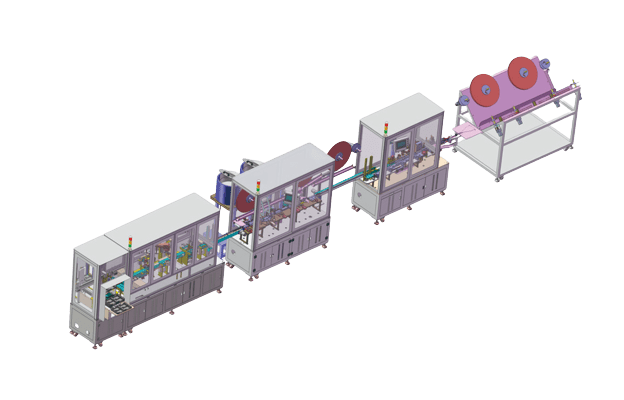

Loading raw materials: The process begins with loading raw materials, such as metal contacts, plastic housings, and other components, into the assembly line. These materials are typically supplied in bulk and need to be sorted and prepared for assembly.

Component preparation: Before assembly, some components may require additional processing, such as cutting, bending, or stamping, to achieve the desired shape and dimensions.

Assembly: The automated assembly line brings together the various components to create the electronic connector. This may involve inserting metal contacts into plastic housings, attaching wires, or assembling multi-part connectors.

Soldering: In some cases, components may need to be soldered together to ensure a secure and reliable electrical connection.

Inspection and testing: After assembly, each connector undergoes rigorous inspection and testing to ensure it meets the required specifications and quality standards.

Flexibility: Choose a system that can accommodate a wide range of connector types and sizes, allowing you to adapt to changing market demands.

Speed and efficiency: Look for an assembly line that offers high-speed operation and minimal downtime to maximize productivity.

Precision and accuracy: Ensure the system can consistently produce connectors that meet your quality standards and tolerances.

Ease of use and maintenance: Opt for a user-friendly system with accessible components for easy maintenance and troubleshooting.

Integration with existing equipment: If you already have some automation in place, make sure the new assembly line can seamlessly integrate with your current setup.

Data collection and reporting: Select a system that offers robust data collection and reporting capabilities to help you monitor performance and identify areas for improvement.

Assess your current process: Before investing in an automated assembly line, thoroughly analyze your existing manufacturing process to identify bottlenecks and areas for improvement.

Set clear goals: Establish clear objectives for your automation project, such as increased production capacity, reduced labor costs, or improved product quality.

Involve your team: Engage your workforce in decision-making and provide training to ensure a smooth transition to the new automated system.

Work with Jxautomated which has only focused on high-speed connectors with wire harness manufacturing automation equipment production line: with a trusted supplier able to provide expert guidance, reliable equipment, and ongoing support throughout the implementation process.

Plan for future growth: Consider your long-term business goals and choose an assembly line that can be easily expanded or upgraded as your needs evolve.

Get notified about new articles