Dongguan City Jiexin Electromechanical Equipment CO., LTD.

15+yrs Professional High-speed connectors & Fakra Cable assemblies automated assembly line & solutions

15+yrs Professional High-speed connectors & Fakra Cable assemblies automated assembly line & solutions

Introduction:

At jxautomated.com, we understand the importance of efficient and precise connector assembly in various industries, including automotive, electronics, and telecommunications. To meet the growing demand for high-quality connectors, we offer state-of-the-art automatic connector assembly machines designed to streamline your production process, reduce labor costs, and ensure consistent product quality. Our advanced technology and engineering expertise guarantee that your connector assembly process is optimized for maximum efficiency and precision.

Product Features:

High-Speed Automation: Our automatic connector assembly machines are designed to maximize throughput and minimize production time. With advanced robotics and automation technology, our machines can quickly and accurately assemble various types of connectors, significantly reducing manual labor and increasing overall productivity.

Precision Assembly: Our machines incorporate high-precision assembly systems to ensure that every connector meets the strictest quality standards. This level of precision helps to reduce defects and improve the overall performance and reliability of your connectors.

Customizable Solutions: We understand that each connector manufacturer has unique requirements and production goals. That’s why we offer customizable automatic connector assembly machines tailored to your specific needs. Our team of experienced engineers will work closely with you to develop a machine that meets your exact specifications and requirements.

User-Friendly Interface: Our automatic connector assembly machines feature an intuitive user interface, making it easy for operators to monitor and control the assembly process. This user-friendly design helps to reduce training time and ensures that your production line runs smoothly and efficiently.

Comprehensive Data Collection and Analysis: Our machines are equipped with advanced data collection and analysis tools, allowing you to monitor and optimize your assembly process in real time. This valuable insight can help you identify areas for improvement and make data-driven decisions to enhance efficiency and productivity.

Product Applications:

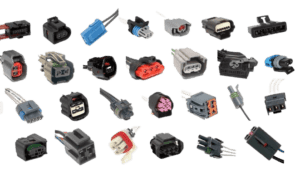

Our automatic connector assembly machines are suitable for a wide range of connector types and applications, including:

Wire-to-Wire Connectors: Streamline the assembly of wire-to-wire connectors used in various systems, such as lighting, power distribution, and sensor connections.

Wire-to-Board Connectors: Improve the efficiency and precision of wire-to-board connector assembly for applications like control modules, infotainment systems, and instrument clusters.

Board-to-Board Connectors: Enhance the assembly process for board-to-board connectors used in electronic control units (ECUs) and other critical systems.

High-Voltage Connectors: Ensure the highest level of quality and reliability for high-voltage connectors used in electric and hybrid vehicle powertrain systems.

Custom Connector Solutions: Our machines can be adapted to accommodate unique connector designs and applications, ensuring that your specific manufacturing needs are met.

Conclusion:

At Jxautomated.com, we are dedicated to providing the most advanced and reliable automatic connector assembly machine solutions in the industry. With our expertise and cutting-edge technology, you can trust that your connector assembly process will be efficient, precise, and capable of meeting the highest quality standards. Contact us today to learn more about our customizable solutions and how we can help you optimize your connector assembly process.

Quality control features: In addition to its vision inspection system, the connector assembly machine may come with other quality control features such as force sensors, torque sensors, and leak tests. These measures ensure that connectors are assembled correctly and adhere to industry standards and customer specifications.

Integrated error detection: Connector assembly machines may also come with integrated error detection systems that detect and correct errors during the production process without operator intervention. This helps to reduce the frequency of human error and ensures that the production process runs smoothly and efficiently.

Data tracking and analysis: Many connector assembly machines come with data tracking and analysis software that allows operators to monitor production performance and identify areas for improvement. These software tools provide real-time production data, such as production rates, reject rates, and downtime, which helps operators make informed decisions about the production process.

Customizable tooling: Connector assembly machines can be customized to suit specific connector types and production requirements. This can include various types of tooling, such as single-insertion and dual-insertion, and custom-designed fixtures and jigs, allowing manufacturers to produce connectors that meet the exact specifications of their customers.

Integration with other manufacturing technologies: Connector assembly machines can be integrated with other manufacturing technologies such as pick-and-place robots and automated testing equipment. This provides manufacturers with increased flexibility and productivity, reduces human operator error, and allows for a more streamlined and efficient production process.

In summary, the connector assembly machine is a highly advanced and sophisticated piece of equipment that can provide manufacturers with increased flexibility, productivity, and quality. With its various features, including quality control, error detection, data tracking, and customizability, it’s an ideal solution for manufacturers looking to enhance their production processes and meet the demands of modern manufacturing.

Get notified about new articles