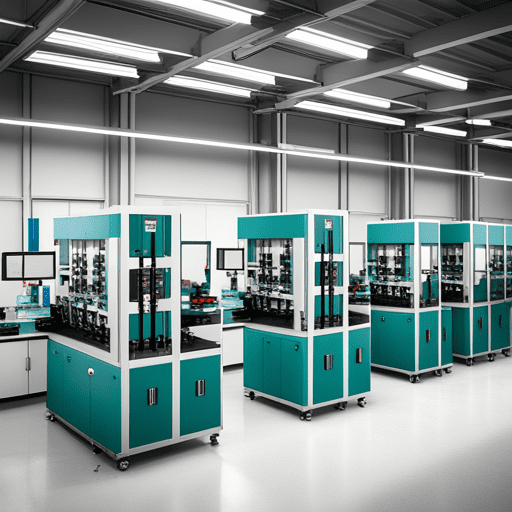

Dongguan City Jiexin Electromechanical Equipment CO., LTD.

15+yrs Professional High-speed connectors & Fakra Cable assemblies automated assembly line & solutions

15+yrs Professional High-speed connectors & Fakra Cable assemblies automated assembly line & solutions

Transformer magnetic assembly equipment production line, including output, processes, risk, advantages, ROI, and after-sales service, the following information may be useful:

Output:

The transformer magnetic assembly equipment production line can be customized to meet different output requirements of the customer. The output of the production line is determined by the size, type, and volume of the transformer magnetic assemblies required. The equipment produces different sizes and types of transformers ranging from small to large capacity. This equipment ensures quality output, lower production costs, and a shorter production cycle.

Processes:

The transformer magnetic assembly production line comprises different machines that work in tandem to manufacture transformer magnetic assemblies. The core shaping machine processes the core, while the winding machine wraps the wire around the core. The pre-assembly machine positions the core and winding in the proper place. The automatic welding machine joins the core and winding, and finally, the testing machine assesses the quality of the finished transformer. The entire process is automated and controlled by computer systems to ensure consistency in output.

Risk:

The production line is not immune to risks, and these may be technical issues, power outages, and human errors, among others. The primary risk factors can be reduced by utilizing quality equipment, hiring trained personnel to operate the machinery, and providing reliable after-sales service.

Advantages:

The transformer magnetic assembly equipment production line has several advantages that make it a valuable investment. Machinery increases production efficiency and productivity, reduces labor costs, improves the accuracy and consistency of the final product, ensures precise control of output quality, and minimizes the risk of errors and defects. A customized production process results in equipment that meets the unique specifications of the customer.

ROI:

The investment in the transformer magnetic assembly equipment production line is substantial. The return on investment (ROI) is determined by several factors, such as initial investment cost, production cycle, output volume, labor costs, maintenance and repair, and market demand. A higher production output translates to higher ROI. However, it is critical to engage with the right supplier and ensure that the production line will operate efficiently, provide quality output, and meet the customer’s needs.

After-sales service:

After-sales service is a crucial aspect of the transformer magnetic assembly equipment production line. Jxautomated.com automation equipment should have a team of well-trained service engineers capable of providing installation, commissioning, training, maintenance, calibration, and software/hardware upgrades to customers. This service includes the provision and supply of replacement parts and consumables to ensure the production line runs without interruptions. Reliable after-sales service maximizes the ROI and enhances customer satisfaction.

Get notified about new articles